Tuning fork

A tuning fork is an acoustic resonator in the form of a two-pronged fork with the prongs (tines) formed from a U-shaped bar of elastic metal (usually steel). It resonates at a specific constant pitch when set vibrating by striking it against a surface or with an object, and emits a pure musical tone after waiting a moment to allow some high overtones to die out. The pitch that a particular tuning fork generates depends on the length of the two prongs. Its main use is as a standard of pitch to tune other musical instruments.

Contents |

Description

The tuning fork was invented in 1711 by British musician John Shore, Sergeant Trumpeter and Lutenist to the court, who had parts specifically written for him by both George Frideric Handel and Henry Purcell.[1]

The main reason for using the fork shape is that, unlike many other types of resonators, it produces a very pure tone, with most of the vibrational energy at the fundamental frequency, and little at the overtones (harmonics). The reason for this is that the frequency of the first overtone is about 52/22 = 25/4 = 6¼ times the fundamental (about 2½ octaves above it).[2] By comparison, the first overtone of a vibrating string or metal bar is only one octave above the fundamental. So when the fork is struck, little of the energy goes into the overtone modes; they also die out correspondingly faster, leaving the fundamental. It is easier to tune other instruments with this pure tone.

Another reason for using the fork shape is that, when it vibrates in its principal mode, the handle vibrates up and down as the prongs move apart and together. There is a node (point of no vibration) at the base of each prong. The handle motion is small, allowing the fork to be held by the handle without damping the vibration, but it allows the handle to transmit the vibration to a resonator (like the hollow rectangular box often used), which amplifies the sound of the fork.[3] Without the resonator (which may be as simple as a table top to which the handle is pressed), the sound is very faint. The reason for this is that the sound waves produced by each fork prong are 180° out of phase with the other, so at a distance from the fork they interfere and largely cancel each other out. If a sound absorbing sheet is slid in between the prongs of a vibrating fork, reducing the waves reaching the ear from one prong, the volume heard will actually increase, due to a reduction of this cancellation.

Although commercial tuning forks are normally tuned to the correct pitch at the factory, they can be retuned by filing material off the prongs. Filing the ends of the prongs raises the pitch, while filing the inside of the base of the prongs lowers it.

Currently, the most common tuning fork sounds the note of A = 440 Hz, because this is the standard concert pitch, which is used as tuning note by some orchestras, it being the pitch of the violin's second string, the first string of the viola, and an octave above the first string of the cello, all played open. Tuning forks used by orchestras between 1750 and 1820 mostly had a frequency of A = 423.5 Hz, although there were many forks and many slightly different pitches.[4] Standard tuning forks are available that vibrate at all the musical pitches within the central octave of the piano, and other pitches. Well-known manufacturers of tuning forks include Ragg and John Walker, both of Sheffield, England.

Calculation of frequency

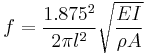

The frequency of a tuning fork depends on its dimensions and the material from which it is made:[5]

Where:

- f is the frequency the fork vibrates at in Hertz.

- 1.875 the smallest positive solution of cos(x)cosh(x) = -1[6].

- l is the length of the prongs in metres.

- E is the Young's modulus of the material the fork is made from in pascals.

- I is the second moment of area of the cross-section in metres to the fourth power.

- ρ is the density of the material the fork is made from in kilogrammes per cubic metre.

- A is the cross-sectional area of the prongs (tines) in square metres.

The ratio  in the equation above can be rewritten as

in the equation above can be rewritten as  if the prongs are cylindrical of radius r, and

if the prongs are cylindrical of radius r, and  if the they have rectangular cross-section of with a along the direction of motion.

if the they have rectangular cross-section of with a along the direction of motion.

Uses

Forks have traditionally been used to tune musical instruments, although electronic tuners are replacing them in many applications. Tuning forks can be driven electrically, by placing electromagnets close to the prongs that are attached to an electronic oscillator circuit, so that their sound does not die out.

In musical instruments

A number of keyboard musical instruments using constructions similar to tuning forks have been made, the most popular of them being the Rhodes piano, which has hammers hitting constructions working on the same principle as tuning forks.

In clocks and watches

The Accutron, an electromechanical watch developed by Max Hetzel and manufactured by Bulova beginning in 1960, used a 360 hertz steel tuning fork powered by a battery as its timekeeping element. The fork allowed it to achieve greater accuracy than conventional balance wheel watches. The humming sound of the tuning fork could be heard when the watch was held to the ear.

Most of today's quartz clocks and watches use 32,768 Hz quartz tuning forks for timekeeping.

Medical and scientific uses

An alternative to the usual A440 diatonic scale is that of philosophical or scientific pitch with standard pitch of C512. According to Rayleigh, the scale was used by physicists and acoustic instrument makers.[7] The tuning fork that John Shore gave to Handel gives a pitch of C512.[8]

Tuning forks, usually C512, are used by medical practitioners to assess a patient's hearing. Lower-pitched ones (usually C128) are also used to check vibration sense as part of the examination of the peripheral nervous system.

Tuning forks also play a role in several alternative medicine modalities, such as sonopuncture and polarity therapy.

Radar gun calibration

A radar gun, typically used for measuring the speed of cars or balls in sports, is usually calibrated with tuning forks.[9][10][11] Instead of the frequency, these forks are labeled with the calibration speed and radar band (e.g. X-Band or K-Band) for which they are calibrated.

In gyroscopes

Doubled and H-type of tuning forks are used for tactical-grade Vibrating Structure Gyroscopes like QuapasonTM and different types of MEMS.[12]

See also

References

- ^ Feldmann, H. (1997). History of the tuning fork. I: Invention of the tuning fork, its course in music and natural sciences. Pubmed.gov. http://www.ncbi.nlm.nih.gov/pubmed/9172630.

- ^ Tyndall, John (1915). Sound. New York: D. Appleton & Co.. p. 156. http://books.google.com/books?id=hCgZAAAAYAAJ&pg=PA156.

- ^ The Science of Sound, 3rd ed., Rossing, Moore, and Wheeler

- ^ The Physics of Musical Instruments amazon.com

- ^ Seon M. Han, Haym Benaroya and Timothy Wei (March 22, 1999) (PDF). Dynamics of Transversely Vibrating Beams using four Engineering Theories. final version. Academic Press. http://csxe.rutgers.edu/research/vibration/51.pdf. Retrieved 2011-11-09.

- ^ Whitney, Scott (1999-04-23). "Vibrations of Cantilever Beams: Deflection, Frequency, and Research Uses". University of Nebraska–Lincoln. http://emweb.unl.edu/Mechanics-Pages/Scott-Whitney/325hweb/Beams.htm. Retrieved 2011-11-09.

- ^ Rayleigh, J.W.S. (1945). The Theory of Sound. New York: Dover. p. 9. ISBN 0-486-60292-3.

- ^ The origin of the tuning fork - nih

- ^ Calibration of Police Radar Instruments, National Bureau of Standards, 1976

- ^ "Radar Gun FAQ". RadarGuns.com. OpticsPlanet, Inc.. 2010. http://www.radarguns.com/radar-guns-faq.html. Retrieved 2010-04-08.

- ^ "A detailed explanation of how police radars work". Radars.com.au. TCG Industrial, Perth, Australia. 2009. http://radars.com.au/police-radar.php. Retrieved 2010-04-08.

- ^ Proceedings of Anniversary Workshop on Solid-State Gyroscopy (19–21 May 2008. Yalta, Ukraine). - Kyiv-Kharkiv. ATS of Ukraine. 2009. - ISBN 978-976-02-5248-6.

External links

- Onlinetuningfork.com, an online tuning fork using Macromedia Flash Player.

- Usneurologicals.com, numerous examples of medical uses of tuning forks.